Piston compressors are powerful equipment commonly used in industrial and workshop applications. However, regular maintenance is essential to ensure continuous performance and extend the lifespan of the device. Piston compressor maintenance involves basic tasks such as proper lubrication, air filter cleaning, and valve inspections. First, the compressor oil level and quality should be monitored continuously. High-quality oil reduces wear on the piston and cylinder surfaces, ensuring efficient operation. Additionally, the air filter should be checked regularly, and any dust or dirt buildup must be cleaned. A dirty air filter causes the motor to work harder and increases energy consumption. The cooling system prevents the compressor from overheating, so it is critical to keep the cooling channels clean. Functional intake and discharge valves maintain pressure balance and prevent energy loss. Checking all hoses, seals, and connections for leaks is also an important part of the maintenance process. Regular piston compressor maintenance prevents breakdowns, improves equipment efficiency, and reduces operating costs. At Gap Kompresör, we recommend not neglecting these essential maintenance steps to keep your compressor performing at its best.

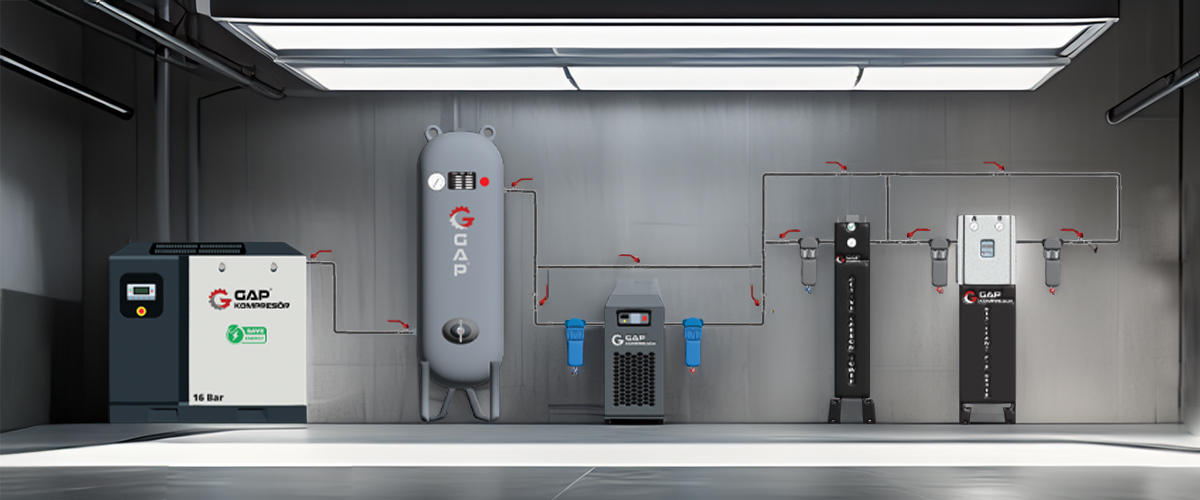

In screw compressor systems, the installation of interconnections is critical for system performance and energy efficiency. The compressed air coming from the compressor must be properly routed and connected through equipment such as the air receiver tank, air dryer, filters, and the distribution piping. First, the pipeline between the screw compressor and the air receiver tank must be sturdy and capable of withstanding pressure. The air receiver tank helps to balance pressure fluctuations and stabilize airflow within the system. Next, the air exiting the tank is directed to the air dryer, where moisture and water are removed. After the dryer, various filters (oil, dust, particulate) are used to improve air quality. The interconnections between filters and other equipment must be leak-proof and secure. Finally, the clean and dry air is delivered to the distribution piping system. Flexible connections should be used to reduce the effects of vibration and thermal expansion on the piping. Additionally, the pipeline should be designed to be as short and direct as possible, minimizing bends to prevent pressure losses. After installation, a pressure test must be conducted to detect and eliminate any air leaks. Properly and professionally installed screw compressor interconnections enhance system efficiency and reduce operational costs. At Gap Kompresör, we are ready to provide technical support for the correct installation of your interconnections.

In industrial production, air compressors play a crucial role in terms of energy efficiency and performance. Screw compressors are generally classified into two main types based on their operating principle: fixed-speed and inverter-driven (variable speed) models. The differences between these two types directly affect operating costs and usage efficiency. Fixed-Speed Screw Compressors operate at a constant motor speed. The compressor runs continuously until the required pressure is reached, then stops or goes into standby mode. This frequent start-stop cycle can lead to increased energy consumption. Fixed-speed compressors are preferred in applications where the air demand is steady and consistent. Inverter-Driven Screw Compressors are advanced systems that adjust motor speed based on demand. Thanks to the inverter, the compressor can increase or decrease motor speed according to the air requirement. This optimizes energy consumption, prevents motor overload, and provides more stable pressure. Inverter-driven compressors are ideal for applications requiring energy savings, variable air demand, and more precise pressure control. In summary, fixed-speed compressors are simpler and have a lower initial cost, while inverter-driven models offer advantages in energy efficiency and performance over the long term. Selecting the right compressor type based on your air demand, usage frequency, and energy costs is critical for efficient and economical operation.

Using the correct oil is critical for the healthy and efficient operation of air compressors. Preventing wear caused by friction between moving parts and ensuring the long service life of the system is only possible with proper maintenance using the right oil at the right time. Regular oil changes, performed in accordance with the compressor manufacturer's recommended oil type and change intervals, will enhance the performance of your machine, help prevent malfunctions, and reduce maintenance costs. Using the right oil provides the following advantages: •Reduces the risk of wear by ensuring effective lubrication of mechanical parts. •Removes heat and contaminants generated during compression from the system. •Enhances sealing between rotors to prevent air leakage. However, over time, oil can become contaminated and form deposits. The main causes of this are: •Using oil that is not suitable for the compressor •Operating at excessively high temperatures •Ingress of dust or dirty air into the system •Mixing different types of oils •Skipping periodic maintenance At GAP Kompresör, we emphasize the importance of choosing the right oil and performing regular maintenance to ensure your equipment operates at peak efficiency. If you are unsure which oil is right for your system, our technical team is ready to offer the most suitable solution for you.

Air compressors are the backbone of industrial facilities, and to operate continuously and efficiently, they require regular maintenance. Without proper care, energy costs rise, performance drops, and the lifespan of the equipment shortens. So, how should compressor maintenance be carried out? And when should you contact an authorized service provider? 1. Basic Stages of Compressor Maintenance Daily Checks: • Checking oil levels • Monitoring pressure readings • Inspecting air output for water or moisture • Identifying any unusual operating sounds Weekly & Monthly Maintenance: • Cleaning or replacing the air filter • Inspecting the oil filter • Checking V-belt tension • Ensuring electrical connections are tight Every 3–6 Months: • Changing the compressor oil • Checking the oil separator • Cleaning the cooling system (fan/radiator) • Updating the control panel software 2. When Should You Contact a Service Technician? You should definitely contact an authorized service provider in the following situations: • Unusual noises are coming from the compressor • The unit frequently stops during operation • Oil leaks are visible • Sudden pressure fluctuations occur • Noticeable increase in energy consumption • Error codes appear on the LCD display These signs may indicate serious internal issues within the compressor. 3. What Does GAP Kompresör Offer? At GAP Kompresör, we don’t just sell products—we also provide professional after-sales technical support. With our nationwide network of authorized service centers, we offer: • Periodic maintenance contracts • Genuine spare parts supply • Emergency intervention teams • Energy efficiency and performance reporting services Neglecting compressor maintenance not only leads to breakdowns but also results in higher operating costs. Regular maintenance is essential to ensure optimal performance and long-term usage of your equipment. Remember: A compressor’s performance is only as strong as the service support behind it. Feel free to contact us for more information about our maintenance and service programs.